AI and Automation Transform EMS Supply Chains

- By Lipika Agarwal

- 23 May 2025

- Business

Artificial Intelligence (AI) and automation technologies are revolutionising how Electronics Manufacturing Services (EMS) companies manage their supply chains. These innovative tools allow EMS providers to work faster, smarter, and more efficiently; AI and automation are becoming essential tools of success as the electronics industry matures.

1. Smarter Demand Forecasting

AI can analyse large amounts of customer data to more accurately forecast customer demand, helping EMS companies avoid shortages and overstocks as well as plan production more effectively while saving both time and money in production/ordering planning processes.

2. Real-Time Inventory Management

Automation tools enable real-time inventory tracking using sensors and software alerting managers when stock is low or there's a delay, helping EMS providers avoid production stoppage and quickly address supply chain disruptions.

3. Faster and More Accurate Production

Robots and automated machines now perform many factory floor tasks more quickly and more accurately than humans ever could, with AI helping optimize production schedules while also cutting waste and improving quality.

4. Predictive Maintenance

AI can detect early warnings of machine failure before it occurs, giving EMS companies time to address problems before they lead to downtime and cost savings. Predictive maintenance saves both money and production from running smoothly.

5. Improved Supplier Management

AI systems assist EMS providers in selecting reliable partners. By analyzing past performance, pricing structures, delivery timeframes, risk analysis, and more, they ensure EMS companies work with only reliable suppliers.

6. Improved Logistics and Delivery

Automation in warehouse and logistics systems--like robotic arms and smart tracking systems--makes product handling and shipping more efficient, while AI helps determine the most expeditious routes for delivery, cutting down delays and costs significantly.

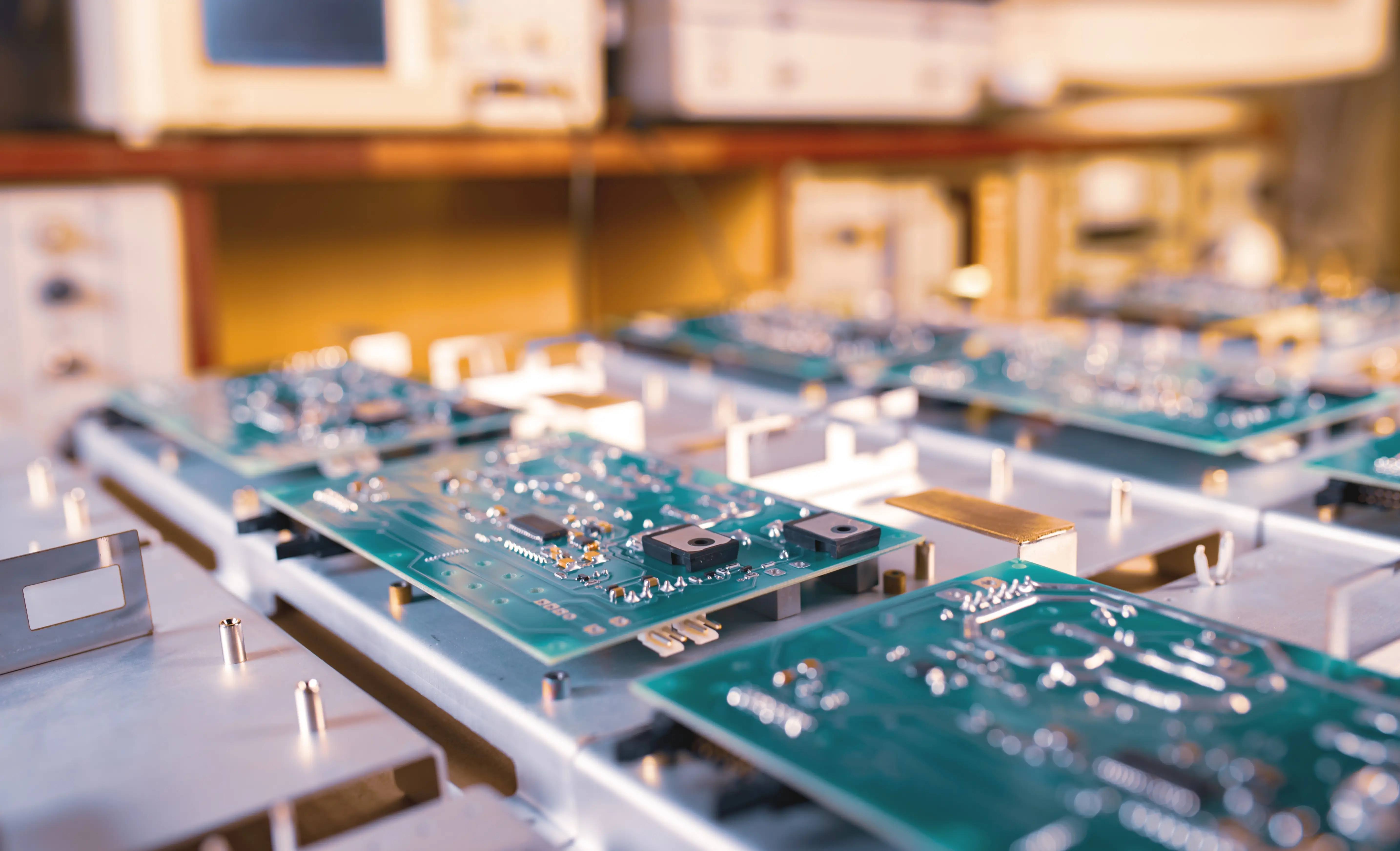

7. Automated Quality Control

AI-powered computer vision systems scan PCBs and assemblies, spotting defects with up to 99.9% accuracy, far surpassing human inspection.

8. Connected Factories & Digital Twins

AI enables “smart factories” where digital twins simulate and monitor production lines in real time—a concept supported by Siemens and Samsung in Industry 4.0 initiatives.

Challenges & Considerations

- Integration issues: Legacy systems may struggle to connect with AI tools, requiring careful planning and IT upgrades.

- Data integrity: AI is only as good as its data—poor input quality undermines outcomes.

- Workforce impact: Automation introduces job displacement fears. Upskilling is essential to empower human-AI collaboration.

- Talent & culture: Shortage of AI-skilled workers and change resistance can stall implementation.

Conclusion

Artificial intelligence and automation are revolutionizing EMS supply chains. From better forecasting to smarter logistics, these technologies are helping EMS companies keep pace in an ever-evolving industry. With increasing adoption rates, AI/automation will continue to boost efficiency, reduce costs, and enhance quality across the board.