EMS vs OEM: Understanding the Key Differences in Electronics Production

- By Lipika Agarwal

- 19 May 2025

- Business

Electronics industries frequently refer to two terms – EMS and OEM – as key terms that play different roles in production processes. If you work in electronics or are planning a tech product launch, you must understand the differences so as not to cause confusion between EMS and OEM companies.

What Is an OEM (Original Equipment Manufacturer)?

An OEM is a company that owns the design and production rights for a particular product, from creating its idea to manufacturing or outsourcing production to an EMS company.

Example: Apple is an OEM that relies on contract manufacturing companies like Foxconn for the production of the iPhone.

What Is Electronics Manufacturing Services (EMS)?

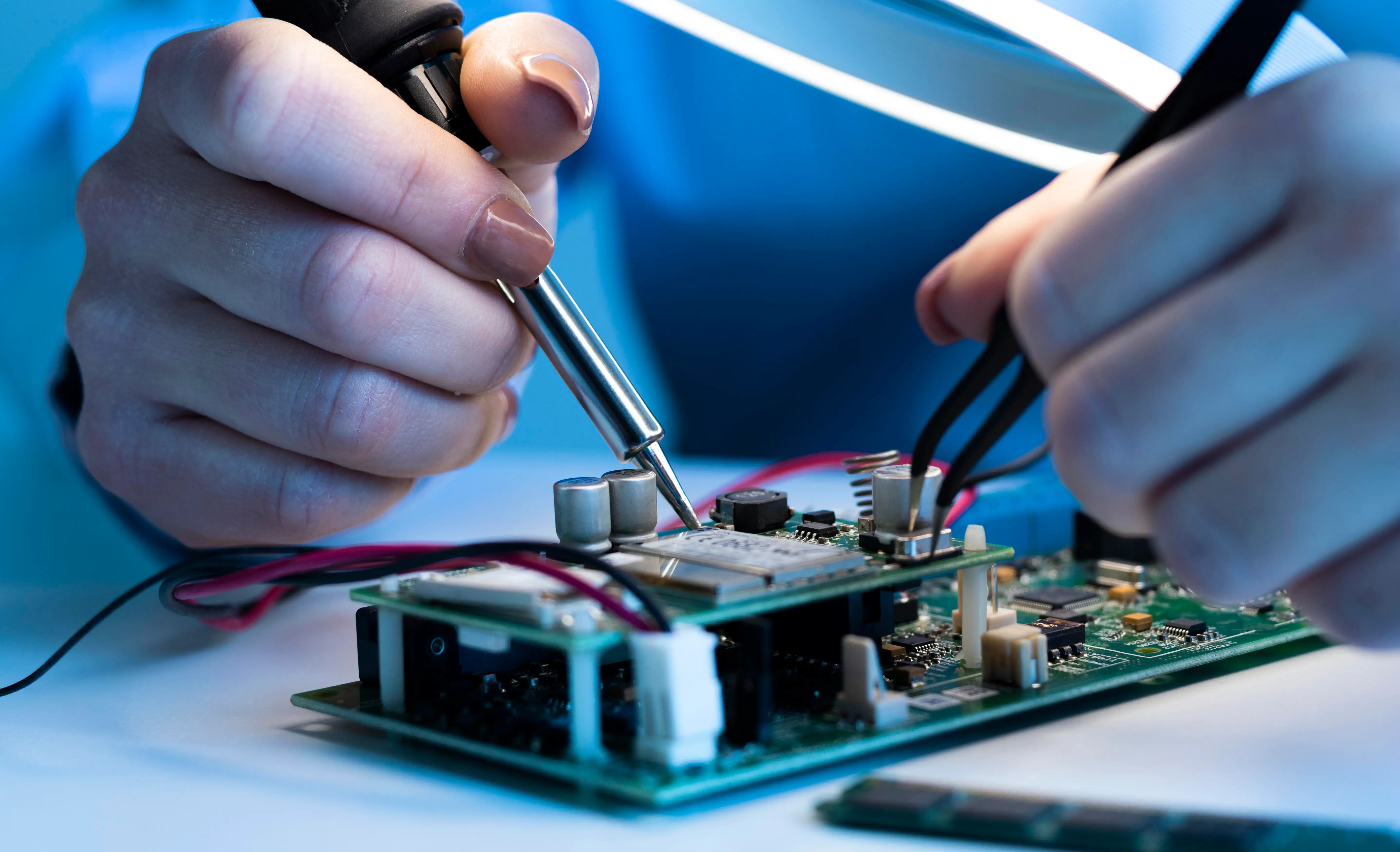

An EMS provider specialises in producing electronic products for OEMs without owning the products themselves or selling under their name; instead, they offer services such as assembly, testing, supply chain management, and design support.

Foxconn is an example of an EMS provider; they manufacture products for Apple, Dell, and many others.

Key Differences Between EMS and OEM

| Feature |

OEM |

EMS |

| Owns the Product |

Yes |

No |

| Focus Area |

Product design, branding, sales |

Manufacturing, testing, logistics |

| Brand Name |

Sells under its brand |

Produces for other brands |

| Manufacturing |

May or may not do it in-house |

The main focus is manufacturing |

| Examples |

Apple, HP, Sony |

Foxconn, Flex, Jabil |

Why OEMs Work with EMS Providers

- Cost Efficiency: EMS companies possess existing facilities, equipment, and skilled employees who make up a cost-efficient service offering.

- Scalability: EMS allows production to quickly meet increasing demands.

- Speed to Market: EMS firms speed production so OEMs can launch products faster.

- Focus: OEMs can focus on innovation and marketing while EMS handles construction.

Modern Trend: OEM + EMS Collaboration

- Many modern OEMs (like Apple or Lenovo) focus entirely on design and branding, leaving all manufacturing to EMS giants like Foxconn or Pegatron.

- This allows leaner operations and global scalability, especially amid supply chain shifts like the China + 1 strategy.

Conclusion

- OEMs are the brains and brand behind a product.

- EMS providers are the muscle—executing mass production with precision and efficiency.

Together, they form the foundation of the modern electronics ecosystem, allowing innovation to scale globally without compromising quality or speed. OEMs and EMS providers play vital roles in the electronics industry. Understanding this relationship allows businesses to make informed decisions when bringing electronic products to market.