India’s EMS Industry Booms with Government’s ‘Make in India’ Push

- By Lipika Agarwal

- 02 May 2025

- Business

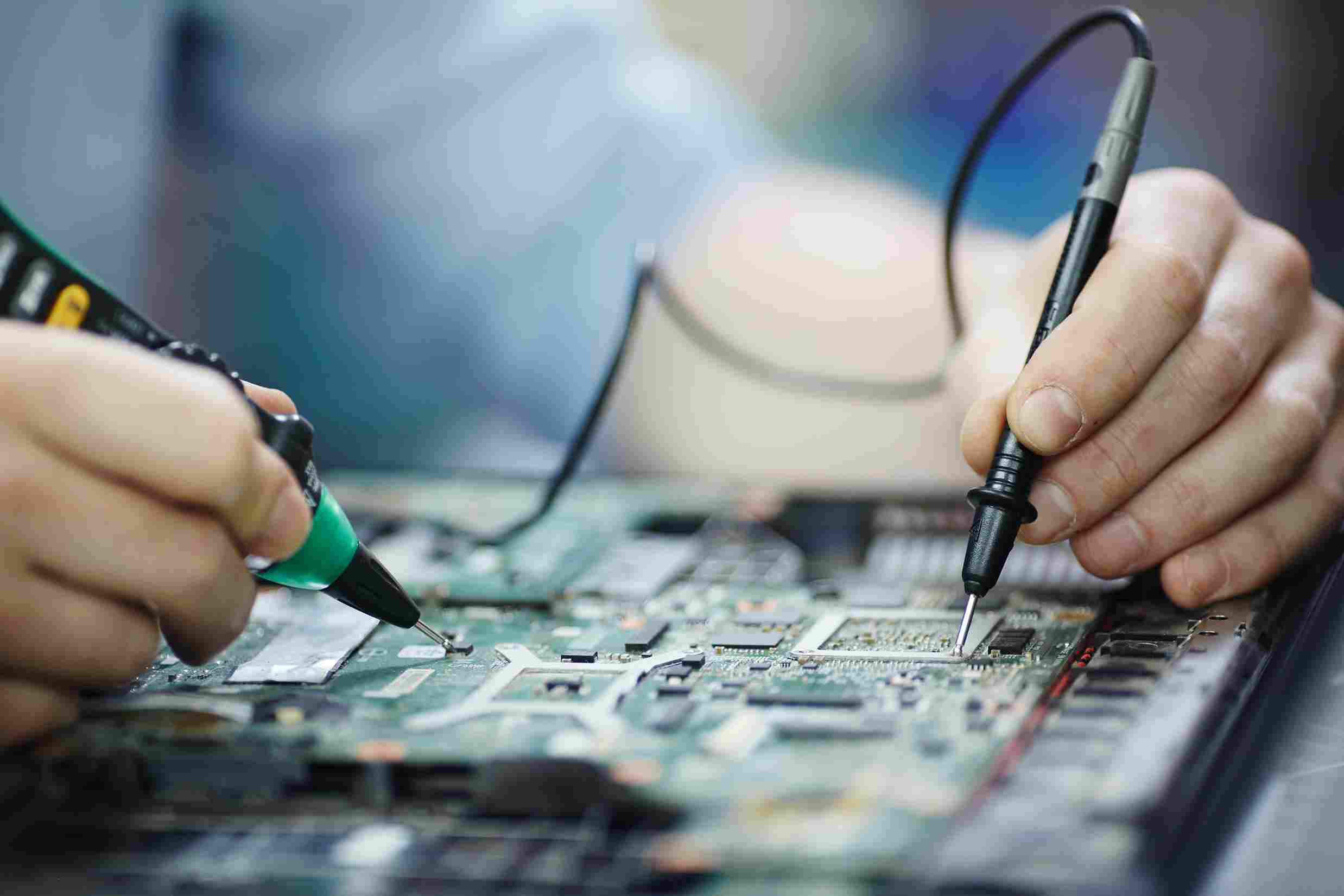

In India, the Electronic Manufacturing Services (EMS) sector is experiencing massive growth, fueled by the ambitious government's “Make in India” initiative and a global shift towards diversification of supply chains. While once a minor manufacturer of electronics in the world, India is now emerging as a central manufacturing hub that produces everything from smartphones and automobile electronic devices to smart wearables and IoT-connected devices.

A New Manufacturing Powerhouse

In the last five years, the Indian EMS sector has grown at a staggering double-digit rate, with forecasts for the industry to reach $300 billion in 2026. Leading global OEMs and contract manufacturers--including Foxconn, Dixon Technologies, and Tata Electronics--have expanded operations in India, citing favourable policies, growing local demand, and a skilled labour force.

“The momentum we're witnessing is unprecedented,” says Rajesh Malhotra, director of EMS major Avalon Technologies. “With government incentives and a renewed focus on indigenous manufacturing, India is quickly becoming a global electronics manufacturing destination.”

Policy-Driven Growth

The success of “Make in India” has been further boosted through targeted programs like the Production Link Incentive (PLI) program that provides an incentive to domestic manufacturers with financial benefits. The government's roadmap for manufacturing that is phased and applies to mobile phones and other components has also facilitated a more localization of manufacturing.

Furthermore, improvements to infrastructure, as well as simplified compliance procedures and a heightened concentration on the logistics aspect and export competitiveness, create an environment in which EMS providers can flourish.

IoT and Next-Gen Electronics in Focus

India's EMS players aren't just focused on traditional assembly. The companies are also looking to invest in areas of high value, like IoT-related gadgets, automobile electronics, medical technology, and consumer wearables. Numerous companies are developing capabilities in embedded system design as well as the technology of surface mount (SMT), as well as advanced fabrication of PCBs.

Design houses in the US and startups are increasingly working with EMS suppliers to test and develop new products, which is further fueling the growth of the ecosystem.

Attracting Global Supply Chains

With global instability along with a determination to lessen dependence on China, multinational corporations are looking to India as an alternative. EMS companies in India are profiting from this shift by offering competitive prices manufacturing solutions that are high-quality, with lower lead times, as well as access to international markets.

“India is not just an option anymore--it's a strategic necessity,” declares Ananya Iyer, supplier chain expert for PwC India. “The convergence of policy, talent, and infrastructure is positioning India as a vital node in the global electronics value chain.”

Challenges and the Road Ahead

Despite the growth, however, the industry is facing problems, which include the need for more complex ecosystems of components, a well-trained workforce formation, as well as the sameness of logistics and power infrastructure. However, stakeholders remain optimistic.

With steady government backing and growing confidence among investors, India's EMS sector is poised to become a significant part of India's economic growth and an essential driving force in the global electronic as well as IoT revolution.